Hi all,

I'm attempting to understand the OPC UA device simulator a little more as I want to simulate a basic device (a limit switch), only, having read through the description of each Function, and, the available Parameters, I'm struggling to understand what each of the Parameters mean for the 'realistic' function.

In my defense, I'm pretty new to the world of OPC/Logic controllers, and, reading through the explanations for each of the associated parameters seems to suggest that they were written with a degree of assumed knowledge.

Being a resourceful type however, I attempted to load up the Generic Device Simulator, which, according to this post here (ok, ok, yeah, it's a 7.9 article...I just can't find the 8.1 equivalent) should contain some examples of it's implementation.

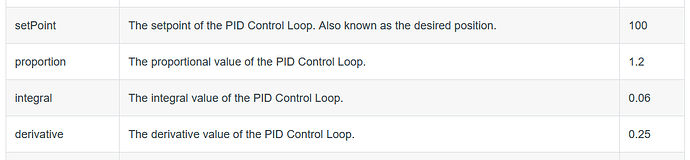

The problem I have with this though is that it suggests the simulator should be representing the Function with the following timings and parameters:

If implemented according to this schema, I assume that this would have given me a fantastic opportunity to better understand this for myself.

However, when I loaded up the simulator, and, proceeded to edit the program, I was presented with the following parameter settings:

I'm not sure I can connect what the article is suggesting with these settings.

Am I correct in thinking that this isn't how it should be configured based upon the settings illustrated in the article, or, am I misunderstanding something here?

Can someone maybe assist me with a more verbose explanation behind each of the parameters used with this function, and, maybe, update the 8.1.x Ignition User Manual website with this information too?

I mean, I suppose i could search the Interwebz for an explanation. However, I couldn't ever be sure that what the internet suggests could be the meaning would tie up exactly with how Inductive Automation have realised/implemented this within Ignition...it being somewhat of its own ecosystem after all.

Many thanks in advance for anything anyone can provide!